Poor Man’s Clock Cleaning, Ingraham – 1918

Having a pendulum kitchen clock puts you into an exclusive club. It’s like having your name in a phone book or having a Facebook account. There are literally tens of thousands of these out there, but that doesn’t mean they aren’t fun to clean and get into top notch working condition. They are particularly interesting since they not only chime the hour and half hour, but actually have an independent alarm with a separate winding mechanism.

I recently acquired a 1918 Ingraham pendulum kitchen clock. This one was a particularly gummed up example. It would run for a few minutes then stop. At this point you have two options to get it running. One, pull the mechanism, run it through a degreaser, clean it, oil it and reassemble (slight oversimplification). Or, two, completely disassemble the mechanism and do a real cleaning then reassemble. I really don’t like option one as the mechanism will likely work fine, but it will still be dull looking. I am also not committed to the disassemble / reassemble option for this particular clock. The paper plate on the face has condition issues and the case isn’t one of my favorites. So, I decided to go with a third very sketchy option and just run the entire mechanism in tact through my sonic cleaner.

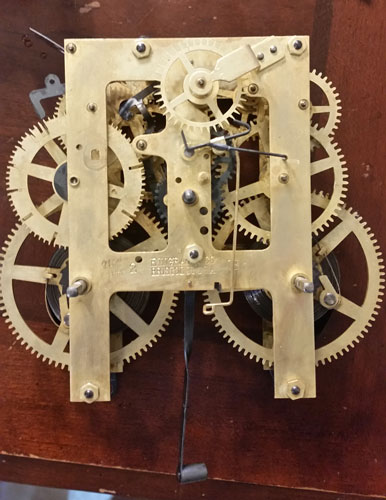

Unfortunately, only about 30% of the mechanism would fit in my cleaner, so I rigged up a way to hang the mechanism in the solution and just flipped it around. This is a total hack, but it actually worked fairly well. After the sonic bath, washing thoroughly, running through an alcohol bath and drying in my home made drying rig, I did some light polishing and wow what a difference. Normally you find these in grungy condition even if they run well. I now realize the part about keeping the patina for these inexpensive clocks is just a way of saying it is too much trouble to properly clean it.

Once assembled I get a real sense of what this clock must have looked like in 1918. Since it is all brass, it would have been bright and shiny and really gleamed in both electric and kerosene light. I decided not to completely polish out the brass mechanism. It has the look of slightly tarnished gold and is wonderful to watch operate.

Long story short, after cleaning, oiling and reassembling the clock, the time is dead on accurate and the mechanism looks beautiful. So much so, I cannot bring myself to put the face plate back on. At least for now I am going to just leave the face plate off and I have painted the hands white to offset against the brass mechanism.

Side Note: The hands were very rusted and the bluing was gone. Otherwise I wouldn’t have painted them.

I can’t say I recommend this technique, but the results were good. It greatly reduced the cleaning time and the end results are better than expected.

Best Cleaning Solution Ever

Best parts cleaning solution formula for sonic cleaner:

- Three (3) Cups Ammonia (Clear – No Lemon Scent)

- One (1) Cup Murphy’s Oil Soap

- One (1) Cup Pine Sol Cleaner (Classic; Do not get off brand or enhanced version)

Ultrasonic Cleaner

Harbor Freight has an inexpensive 2.5 Liter Ultrasonic Cleaner that can handle most jobs. It is heated and has varying timer setting lengths. The smaller version is fine for watch cleaning, but just can’t handle larger mantle clocks.

http://www.harborfreight.com/25-liter-ultrasonic-cleaner-63256.html

Photos… ENJOY!